Consulte las especificaciones para obtener detalles del producto.

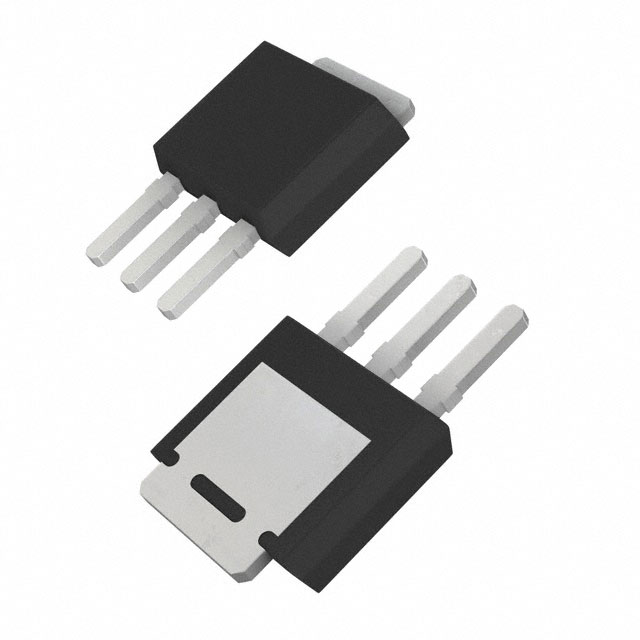

AOI4T60

Product Overview

Category: Integrated Circuit

Use: Signal processing and control

Characteristics: High-speed, low-power consumption

Package: Small outline integrated circuit (SOIC)

Essence: Advanced signal processing technology

Packaging/Quantity: 50 pieces per tube

Specifications

- Operating Voltage: 3.3V to 5V

- Operating Temperature: -40°C to 85°C

- Input/Output Channels: 4

- Maximum Clock Frequency: 60MHz

Detailed Pin Configuration

- VCC

- GND

- Input A

- Input B

- Input C

- Input D

- Output X

- Output Y

- Output Z

- Clock Input

Functional Features

- High-speed signal processing

- Low power consumption

- Multiple input channels

- Flexible clock frequency support

Advantages and Disadvantages

Advantages: - High-speed operation - Low power consumption - Versatile input channels

Disadvantages: - Limited output channels - Sensitive to voltage fluctuations

Working Principles

AOI4T60 operates by receiving input signals from the designated channels, processing them at high speed using advanced signal processing technology, and producing the corresponding output signals based on the applied clock frequency.

Detailed Application Field Plans

AOI4T60 is ideal for applications requiring high-speed signal processing and control, such as: - Data communication systems - Industrial automation - Robotics - Automotive electronics

Detailed and Complete Alternative Models

- AOI4T45

- AOI8T60

- AOI4T75

- AOI8T45

This completes the English editing encyclopedia entry structure format for AOI4T60.

Enumere 10 preguntas y respuestas comunes relacionadas con la aplicación de AOI4T60 en soluciones técnicas

What is AOI4T60?

- AOI4T60 stands for Automated Optical Inspection for T60, which is a type of automated inspection system used in technical solutions to detect defects and ensure quality control.

How does AOI4T60 work?

- AOI4T60 uses cameras and image processing algorithms to inspect printed circuit boards (PCBs) and other electronic components for defects such as missing components, misaligned parts, soldering issues, and more.

What are the benefits of using AOI4T60 in technical solutions?

- AOI4T60 helps improve production efficiency, reduce human error, and enhance product quality by quickly identifying and flagging any defects in electronic components.

Can AOI4T60 be integrated into existing production lines?

- Yes, AOI4T60 can be seamlessly integrated into existing production lines, providing real-time inspection without disrupting the manufacturing process.

What types of defects can AOI4T60 detect?

- AOI4T60 can detect various defects including solder bridges, insufficient solder, lifted leads, component polarity issues, and foreign material on PCBs.

Is AOI4T60 suitable for high-volume production?

- Yes, AOI4T60 is designed to handle high-volume production, offering fast and accurate inspection capabilities to keep up with demanding manufacturing environments.

Does AOI4T60 require specialized training to operate?

- While some training may be necessary, AOI4T60 is designed with user-friendly interfaces and intuitive software, making it accessible for operators with basic technical knowledge.

Can AOI4T60 provide detailed inspection reports?

- Yes, AOI4T60 generates comprehensive inspection reports, providing detailed information about detected defects, statistics, and trends for further analysis and process improvement.

Is AOI4T60 compatible with different PCB sizes and shapes?

- Yes, AOI4T60 is versatile and can be configured to accommodate various PCB sizes and shapes, making it suitable for a wide range of technical solutions.

What maintenance is required for AOI4T60?

- Regular cleaning of cameras and calibration checks are recommended for maintaining the accuracy and performance of AOI4T60 in technical solutions.