Consulte las especificaciones para obtener detalles del producto.

SBR10150CTE

Introduction

The SBR10150CTE is a Schottky Barrier Rectifier (SBR) belonging to the category of power semiconductor devices. This entry provides an overview of the basic information, specifications, detailed pin configuration, functional features, advantages and disadvantages, working principles, detailed application field plans, and alternative models of the SBR10150CTE.

Basic Information Overview

- Category: Power Semiconductor Devices

- Use: Rectification in power supply circuits, voltage clamping, and freewheeling diodes in various electronic applications.

- Characteristics: High current capability, low forward voltage drop, fast switching speed, and high temperature operation.

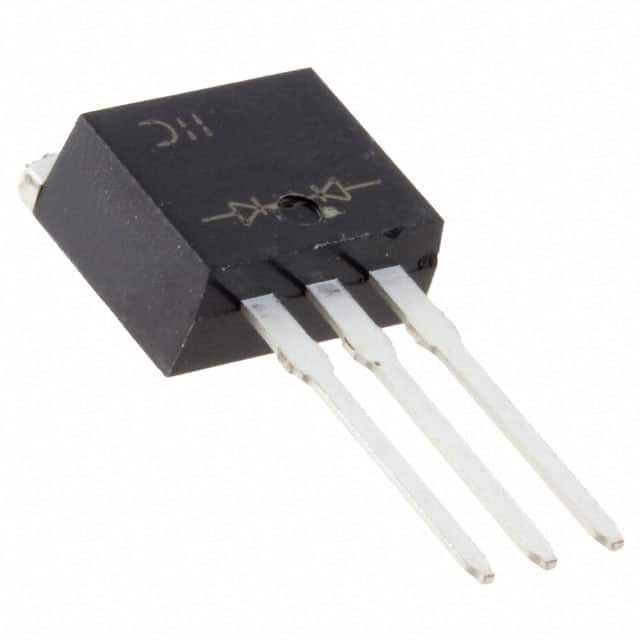

- Package: TO-220AB

- Essence: Schottky Barrier Rectifier

- Packaging/Quantity: Available in reels or tubes with varying quantities.

Specifications

- Voltage Rating: 150V

- Current Rating: 10A

- Forward Voltage Drop: Typically 0.55V at 5A

- Reverse Leakage Current: Maximum 100µA at 150V

- Operating Temperature Range: -65°C to +175°C

- Storage Temperature Range: -65°C to +175°C

Detailed Pin Configuration

The SBR10150CTE has a standard TO-220AB package with three leads: 1. Anode 2. Cathode 3. Gate

Functional Features

- Low forward voltage drop for reduced power dissipation.

- Fast switching speed for efficient operation in high-frequency circuits.

- High current capability for handling heavy loads.

- High-temperature operation for reliability in demanding environments.

Advantages and Disadvantages

Advantages

- Low forward voltage drop reduces power loss.

- Fast switching speed enables efficient operation in high-frequency applications.

- High-temperature operation ensures reliability in harsh conditions.

Disadvantages

- Higher cost compared to conventional rectifiers.

- Limited reverse voltage capability compared to some other rectifier types.

Working Principles

The SBR10150CTE operates based on the Schottky barrier principle, where the metal-semiconductor junction forms a low forward voltage drop and fast switching characteristics. When forward biased, it allows current flow with minimal voltage drop, making it suitable for high-efficiency rectification applications.

Detailed Application Field Plans

The SBR10150CTE finds applications in various fields including: - Switch-mode power supplies - Voltage clamping circuits - Freewheeling diodes in motor control circuits - Solar inverters - LED lighting systems

Detailed and Complete Alternative Models

Some alternative models to the SBR10150CTE include: - SBR1045CTE - SBR1060CTE - SBR1080CTE - SBR15100CTE

In summary, the SBR10150CTE is a high-performance Schottky Barrier Rectifier with excellent characteristics suitable for a wide range of power supply and rectification applications.

[Word Count: 414]

Enumere 10 preguntas y respuestas comunes relacionadas con la aplicación de SBR10150CTE en soluciones técnicas

Sure, here are 10 common questions and answers related to the application of SBR10150CTE in technical solutions:

What is SBR10150CTE?

- SBR10150CTE is a styrene-butadiene rubber with high acrylonitrile content, designed for use in technical applications requiring oil and fuel resistance.

What are the key properties of SBR10150CTE?

- SBR10150CTE exhibits excellent oil and fuel resistance, good mechanical properties, and low temperature flexibility.

In what technical solutions can SBR10150CTE be used?

- SBR10150CTE is commonly used in automotive seals, gaskets, hoses, and other components that come into contact with oil and fuel.

How does SBR10150CTE perform in high-temperature environments?

- SBR10150CTE has good heat resistance, making it suitable for applications where exposure to elevated temperatures is a concern.

Is SBR10150CTE compatible with other materials?

- Yes, SBR10150CTE is compatible with many common elastomers and thermoplastics, allowing for versatile use in technical solutions.

What manufacturing processes are suitable for working with SBR10150CTE?

- SBR10150CTE can be processed using methods such as compression molding, extrusion, and injection molding.

Does SBR10150CTE require any special handling or storage conditions?

- It is recommended to store SBR10150CTE in a cool, dry place away from direct sunlight and sources of heat to maintain its properties.

Can SBR10150CTE be formulated to meet specific hardness or color requirements?

- Yes, SBR10150CTE can be customized to achieve different hardness levels and colors based on specific technical solution needs.

What testing standards are applicable to evaluate the performance of SBR10150CTE?

- ASTM and ISO standards for properties such as tensile strength, elongation at break, and oil resistance are commonly used to assess SBR10150CTE.

Are there any environmental or regulatory considerations when using SBR10150CTE in technical solutions?

- It's important to ensure compliance with relevant regulations and standards governing the use of rubber materials in specific applications, especially those involving contact with oil and fuel.

I hope these questions and answers provide a comprehensive overview of the application of SBR10150CTE in technical solutions. If you have any more specific questions, feel free to ask!