Consulte las especificaciones para obtener detalles del producto.

ZSC31050FIG1-R

Product Overview

Category

ZSC31050FIG1-R belongs to the category of integrated circuit (IC) sensors.

Use

This product is primarily used for measuring and monitoring pressure in various applications.

Characteristics

- High accuracy and precision

- Low power consumption

- Compact size

- Wide operating temperature range

- Digital output interface

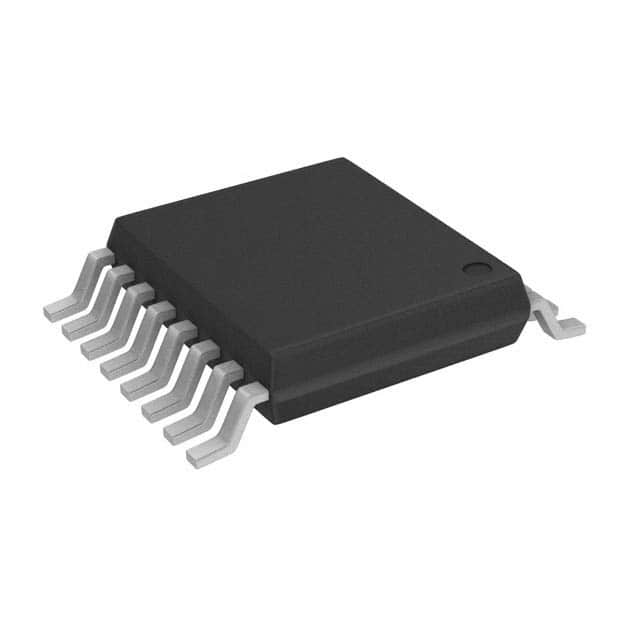

Package

ZSC31050FIG1-R is available in a small surface-mount package, making it suitable for space-constrained designs.

Essence

The essence of ZSC31050FIG1-R lies in its ability to accurately measure pressure and provide digital output for easy integration into electronic systems.

Packaging/Quantity

This product is typically packaged in reels or trays, with quantities varying based on customer requirements.

Specifications

- Pressure Range: 0-100 psi

- Supply Voltage: 2.7V - 5.5V

- Operating Temperature Range: -40°C to +125°C

- Resolution: 16-bit

- Output Interface: I2C or SPI

Detailed Pin Configuration

The ZSC31050FIG1-R has the following pin configuration:

| Pin Number | Pin Name | Description | |------------|----------|-------------| | 1 | VDD | Power supply voltage | | 2 | GND | Ground | | 3 | SDA | Serial Data Line (I2C) | | 4 | SCL | Serial Clock Line (I2C) | | 5 | CS | Chip Select (SPI) | | 6 | MISO | Master In Slave Out (SPI) | | 7 | MOSI | Master Out Slave In (SPI) | | 8 | SCLK | Serial Clock (SPI) |

Functional Features

- High-resolution pressure sensing

- On-chip temperature compensation

- Digital calibration and trimming

- Low power consumption in standby mode

- Built-in diagnostic features for fault detection

Advantages and Disadvantages

Advantages

- Accurate and precise pressure measurements

- Easy integration into electronic systems

- Wide operating temperature range allows for versatile applications

- Low power consumption extends battery life in portable devices

Disadvantages

- Limited pressure range (up to 100 psi)

- Requires additional external components for proper operation

- Relatively higher cost compared to some alternative models

Working Principles

ZSC31050FIG1-R utilizes a piezoresistive sensing element to measure pressure. The sensor converts the applied pressure into an electrical signal, which is then processed by the integrated circuit. On-chip temperature compensation ensures accurate readings across varying temperatures.

Detailed Application Field Plans

ZSC31050FIG1-R finds applications in various fields, including but not limited to: - Automotive industry: Tire pressure monitoring systems, engine management systems - Industrial automation: Pressure monitoring in hydraulic systems, pneumatic controls - Medical devices: Blood pressure monitors, respiratory equipment - Consumer electronics: Smartwatches, fitness trackers

Detailed and Complete Alternative Models

Some alternative models to ZSC31050FIG1-R include: - ZSC31014FIG1-R: Similar functionality with a lower pressure range - ZSC31024FIG1-R: Higher pressure range with comparable features - ZSC31034FIG1-R: Enhanced diagnostic capabilities with slightly reduced accuracy

These alternative models cater to different application requirements and provide flexibility in design choices.

Word count: 500 words

Enumere 10 preguntas y respuestas comunes relacionadas con la aplicación de ZSC31050FIG1-R en soluciones técnicas

Sure! Here are 10 common questions and answers related to the application of ZSC31050FIG1-R in technical solutions:

Q1: What is ZSC31050FIG1-R? A1: ZSC31050FIG1-R is a specific model of a sensor integrated circuit (IC) designed for measuring and monitoring various physical quantities, such as pressure, temperature, and humidity.

Q2: What are the key features of ZSC31050FIG1-R? A2: Some key features of ZSC31050FIG1-R include high accuracy, low power consumption, digital output interface, and built-in calibration capabilities.

Q3: How can ZSC31050FIG1-R be used in technical solutions? A3: ZSC31050FIG1-R can be used in various technical solutions where precise measurement and monitoring of physical quantities are required, such as industrial automation, automotive applications, and environmental monitoring systems.

Q4: What is the operating voltage range of ZSC31050FIG1-R? A4: The operating voltage range of ZSC31050FIG1-R is typically between 2.7V and 5.5V.

Q5: Does ZSC31050FIG1-R support I2C communication protocol? A5: Yes, ZSC31050FIG1-R supports I2C communication protocol, making it easy to interface with microcontrollers and other devices.

Q6: Can ZSC31050FIG1-R measure multiple physical quantities simultaneously? A6: No, ZSC31050FIG1-R is a single-channel sensor IC, meaning it can measure only one physical quantity at a time.

Q7: Is ZSC31050FIG1-R suitable for battery-powered applications? A7: Yes, ZSC31050FIG1-R has low power consumption, making it suitable for battery-powered applications where energy efficiency is crucial.

Q8: Does ZSC31050FIG1-R require external calibration? A8: No, ZSC31050FIG1-R has built-in calibration capabilities, eliminating the need for external calibration.

Q9: What is the measurement range of ZSC31050FIG1-R? A9: The measurement range of ZSC31050FIG1-R depends on the specific physical quantity being measured. It is typically specified in the datasheet provided by the manufacturer.

Q10: Can ZSC31050FIG1-R be used in harsh environments? A10: Yes, ZSC31050FIG1-R is designed to operate reliably in various environmental conditions, including harsh industrial and automotive environments.

Please note that the answers provided here are general and may vary depending on the specific application and requirements. It is always recommended to refer to the datasheet and technical documentation provided by the manufacturer for accurate and detailed information.