Consulte las especificaciones para obtener detalles del producto.

FEP16CTA

Product Overview

Category

The FEP16CTA belongs to the category of semiconductor devices, specifically within the family of fast recovery rectifiers.

Use

This product is commonly used in power supply applications, inverters, and other electronic circuits where fast switching and high efficiency are required.

Characteristics

- Fast recovery time

- High efficiency

- Low forward voltage drop

- High surge capability

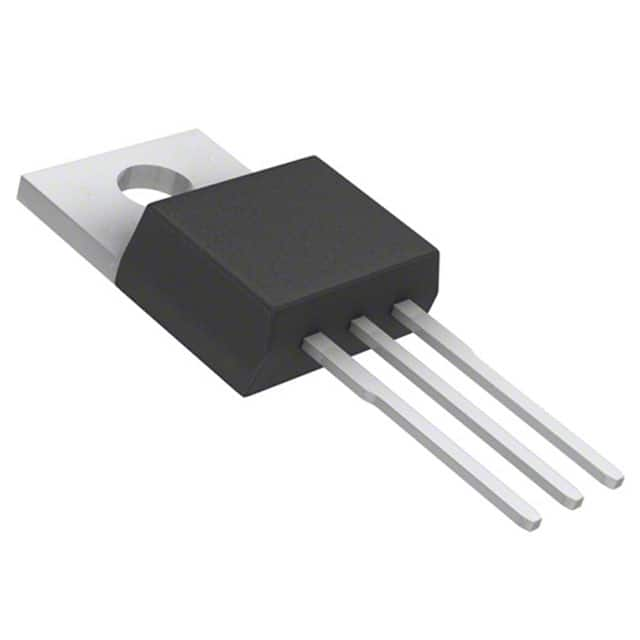

Package

The FEP16CTA is typically available in a compact, surface-mount package, making it suitable for modern electronic designs.

Essence

The essence of the FEP16CTA lies in its ability to efficiently convert alternating current (AC) to direct current (DC) with minimal power loss.

Packaging/Quantity

It is usually supplied in reels or tubes, with quantities varying based on manufacturer specifications.

Specifications

- Maximum Average Forward Current: 16A

- Reverse Voltage: 200V

- Forward Voltage Drop: 0.95V at 16A

- Reverse Recovery Time: 35ns

- Operating Temperature Range: -55°C to 175°C

Detailed Pin Configuration

The FEP16CTA typically has a standard pin configuration with two leads for connection to the circuit board. The datasheet provided by the manufacturer should be referenced for specific details.

Functional Features

- Fast recovery time for improved efficiency

- Low forward voltage drop for reduced power dissipation

- High surge capability for reliable operation in demanding conditions

Advantages and Disadvantages

Advantages

- High efficiency

- Fast recovery time

- Low power dissipation

Disadvantages

- Limited reverse voltage compared to some alternative models

- Sensitive to overvoltage conditions

Working Principles

The FEP16CTA operates based on the principles of semiconductor physics, utilizing its unique material properties to facilitate the rapid and efficient conversion of electrical energy.

Detailed Application Field Plans

The FEP16CTA is well-suited for use in: - Switch-mode power supplies - Motor drives - Inverters - Converters

Detailed and Complete Alternative Models

Some alternative models to the FEP16CTA include: - FEP20CTA: Higher reverse voltage rating - FEP10CTA: Lower forward current rating - FEP16DTA: Dual diode configuration for bridge rectifier applications

In conclusion, the FEP16CTA offers a balance of efficiency and performance, making it a versatile component in various power electronics applications.

Word count: 349

Enumere 10 preguntas y respuestas comunes relacionadas con la aplicación de FEP16CTA en soluciones técnicas

What is FEP16CTA?

- FEP16CTA is a type of fluorinated ethylene propylene (FEP) material known for its high chemical resistance and electrical insulation properties.

What are the key technical properties of FEP16CTA?

- FEP16CTA exhibits excellent thermal stability, low friction, high dielectric strength, and resistance to chemicals and solvents.

In what applications can FEP16CTA be used?

- FEP16CTA is commonly used in wire and cable insulation, semiconductor manufacturing, chemical processing equipment, and as a coating for non-stick surfaces.

How does FEP16CTA compare to other fluoropolymers like PTFE or PVDF?

- FEP16CTA offers similar chemical resistance to PTFE and PVDF but has better clarity and flexibility, making it suitable for applications requiring transparency and bendability.

What temperature range can FEP16CTA withstand?

- FEP16CTA can typically withstand temperatures ranging from -200°C to 200°C, making it suitable for both cryogenic and high-temperature applications.

Is FEP16CTA suitable for outdoor use?

- Yes, FEP16CTA is UV resistant and can withstand exposure to outdoor environmental conditions without significant degradation.

Can FEP16CTA be bonded or welded to other materials?

- Yes, FEP16CTA can be bonded using adhesives designed for fluoropolymers, and it can also be welded to itself or to other FEP materials.

What are the considerations for machining or fabricating FEP16CTA?

- FEP16CTA should be machined using sharp tools at low speeds to prevent overheating, and it can be easily formed using standard thermoforming techniques.

Does FEP16CTA comply with any industry standards or regulations?

- FEP16CTA may comply with various industry standards such as UL 94V-0 for flammability and FDA regulations for food contact applications.

Are there any special storage or handling requirements for FEP16CTA?

- FEP16CTA should be stored in a cool, dry place away from direct sunlight and should be handled with clean gloves to avoid contamination.