Consulte las especificaciones para obtener detalles del producto.

UMG3NTR Product Overview

Introduction

UMG3NTR is a versatile electronic component that belongs to the category of integrated circuits. It is widely used in various electronic devices and systems due to its unique characteristics and functional features.

Basic Information Overview

- Category: Integrated Circuit

- Use: UMG3NTR is utilized for signal processing, amplification, and control in electronic devices.

- Characteristics: The UMG3NTR is known for its high precision, low power consumption, and compact design.

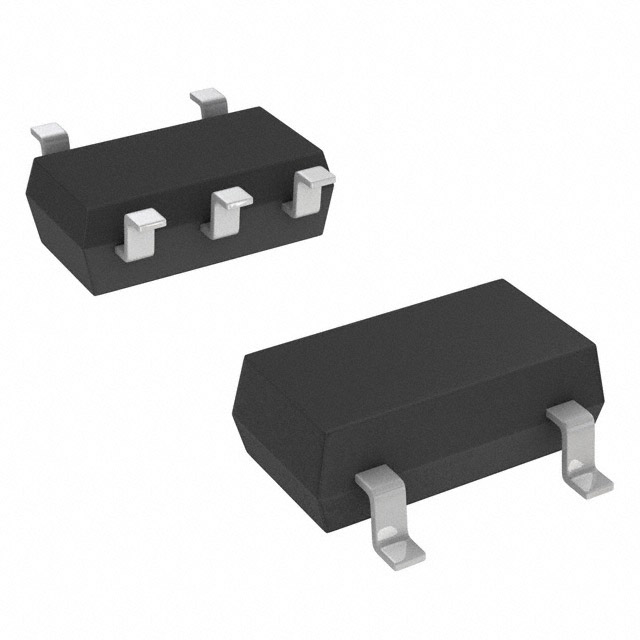

- Package: The UMG3NTR is available in a small form factor package, making it suitable for space-constrained applications.

- Essence: This integrated circuit is essential for enhancing the performance and functionality of electronic systems.

- Packaging/Quantity: The UMG3NTR is typically packaged in reels containing a specific quantity based on the manufacturer's specifications.

Specifications

The UMG3NTR integrated circuit has the following specifications: - Input Voltage Range: 3V to 5V - Operating Temperature: -40°C to 85°C - Output Current: 100mA - Frequency Response: 1Hz to 1MHz - Package Type: SOT-23

Detailed Pin Configuration

The UMG3NTR integrated circuit features a standard pin configuration with the following pinout: 1. VCC (Power Supply) 2. GND (Ground) 3. IN (Input) 4. OUT (Output)

Functional Features

- Signal Amplification: UMG3NTR provides high-quality amplification of input signals with minimal distortion.

- Low Power Consumption: The integrated circuit is designed to operate efficiently while consuming minimal power.

- Precision Control: UMG3NTR offers precise control over output signals, making it suitable for applications requiring accuracy.

Advantages and Disadvantages

Advantages

- Compact Design: UMG3NTR's small form factor enables integration into space-limited electronic devices.

- High Precision: The integrated circuit delivers accurate signal processing and control.

- Low Power Consumption: UMG3NTR helps in reducing overall power usage in electronic systems.

Disadvantages

- Limited Output Current: The UMG3NTR may not be suitable for applications requiring high output current levels.

- Temperature Sensitivity: The operating temperature range of UMG3NTR is limited, which may restrict its use in extreme environments.

Working Principles

UMG3NTR operates based on the principles of signal amplification and control. It processes input signals, amplifies them with precision, and delivers the controlled output as per the application requirements.

Detailed Application Field Plans

UMG3NTR finds extensive application in various fields, including: - Audio Amplification Systems - Sensor Signal Processing - Battery Management Systems - Portable Electronic Devices

Detailed and Complete Alternative Models

Some alternative models to UMG3NTR include: - UMG4NTR: A higher-output current version of UMG3NTR with similar characteristics. - UMG2NTR: A lower-power consumption variant suitable for battery-operated devices.

In conclusion, UMG3NTR is a valuable integrated circuit with diverse applications and significant advantages for electronic system design and development.

Word Count: 443

Enumere 10 preguntas y respuestas comunes relacionadas con la aplicación de UMG3NTR en soluciones técnicas

What is UMG3NTR?

- UMG3NTR is a specialized material used in technical solutions, known for its high strength and resistance to various environmental conditions.

How is UMG3NTR typically used in technical solutions?

- UMG3NTR is commonly used in applications such as aerospace components, automotive parts, and industrial machinery due to its durability and reliability.

What are the key properties of UMG3NTR that make it suitable for technical solutions?

- UMG3NTR exhibits high tensile strength, excellent corrosion resistance, and thermal stability, making it ideal for demanding technical applications.

Are there specific fabrication techniques required when working with UMG3NTR?

- Yes, UMG3NTR often requires specialized machining and forming processes due to its hardness and toughness, which may include precision grinding or electrical discharge machining (EDM).

Can UMG3NTR be welded or joined to other materials?

- UMG3NTR can be challenging to weld due to its high strength and heat resistance, but it can be joined using advanced welding methods such as laser welding or friction stir welding.

What are the temperature limits for UMG3NTR in technical applications?

- UMG3NTR can withstand temperatures ranging from -200°C to 500°C, making it suitable for use in both cryogenic and high-temperature environments.

Does UMG3NTR require any special surface treatments for specific technical applications?

- Depending on the application, UMG3NTR may benefit from surface treatments such as coatings or plating to enhance its wear resistance or improve its compatibility with certain environments.

Is UMG3NTR compatible with common engineering plastics and elastomers?

- UMG3NTR is generally compatible with a wide range of engineering plastics and elastomers, making it versatile for use in composite materials and hybrid components.

What are the considerations for designing components with UMG3NTR in technical solutions?

- Designers should consider the material's high strength, stiffness, and dimensional stability when integrating UMG3NTR into technical solutions, as well as the need for precision machining.

Are there any specific safety or handling precautions associated with UMG3NTR in technical applications?

- When working with UMG3NTR, proper ventilation and personal protective equipment should be used during machining or processing to minimize exposure to fine particles and dust.