Consulte las especificaciones para obtener detalles del producto.

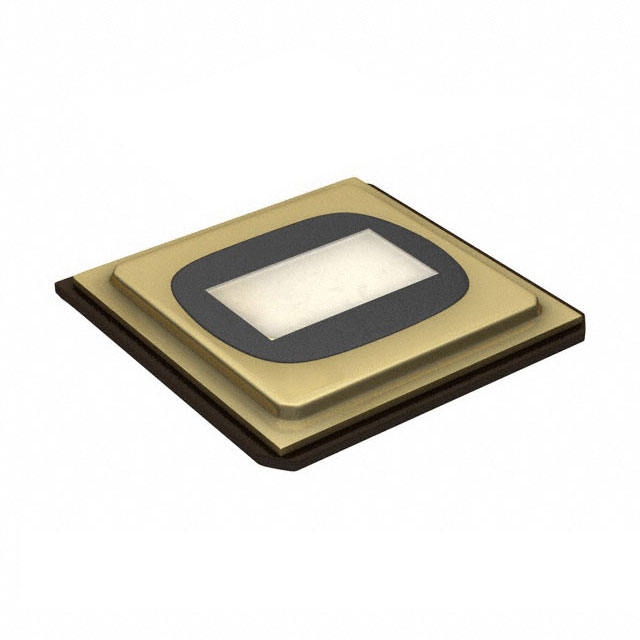

DLP9500UVFLN

Product Overview

Category

The DLP9500UVFLN belongs to the category of Digital Micromirror Devices (DMDs).

Use

It is primarily used in applications that require high-resolution and high-speed pattern generation, such as 3D printing, lithography, and advanced imaging systems.

Characteristics

- High resolution: The DLP9500UVFLN offers a resolution of up to 4 million micromirrors, enabling precise pattern generation.

- High speed: With its fast switching speed, it can achieve high frame rates, allowing for rapid pattern updates.

- UV compatibility: This device is specifically designed for ultraviolet (UV) light applications, making it suitable for UV-based processes.

- Compact package: The DLP9500UVFLN comes in a compact form factor, facilitating integration into various systems.

- High reliability: It is built with robust materials and undergoes rigorous testing to ensure long-term performance.

Package and Quantity

The DLP9500UVFLN is available in a ceramic LCC package. Each package contains one DLP9500UVFLN device.

Specifications

- Micromirror array size: 2560 x 1600 pixels

- Micromirror pitch: 7.6 μm

- Micromirror tilt angle: ±12 degrees

- Operating wavelength range: 350 - 450 nm

- Frame rate: Up to 9,523 Hz

- Power supply voltage: 5 V

- Power consumption: 2.5 W (typical)

Pin Configuration

The DLP9500UVFLN has the following pin configuration:

- VDD - Power supply voltage (5 V)

- GND - Ground

- SDA - I2C serial data input

- SCL - I2C serial clock input

- VSYNC - Vertical synchronization input

- HSYNC - Horizontal synchronization input

- XCLK - External pixel clock input

- DIN0-DIN23 - Data input pins

- DMD_RESET - Device reset input

- DMD_CLK - Internal clock output

Functional Features

- High-resolution pattern generation: The DLP9500UVFLN can produce intricate patterns with its large micromirror array, enabling precise control over projected images.

- Fast pattern updates: With its high frame rate capability, it allows for rapid pattern updates, reducing image flickering and improving overall system performance.

- UV compatibility: Designed specifically for UV applications, it ensures accurate and reliable pattern projection in UV-based processes.

- Flexible control interface: The device supports I2C communication, allowing for easy integration and control within existing systems.

Advantages and Disadvantages

Advantages

- High resolution and fast switching speed enable precise and smooth pattern generation.

- UV compatibility makes it suitable for a wide range of UV-based applications.

- Compact package facilitates integration into various systems.

- Flexible control interface simplifies system integration.

Disadvantages

- Limited operating wavelength range restricts its use to UV applications only.

- Higher power consumption compared to some alternative models.

- Relatively higher cost compared to lower-end DMDs.

Working Principles

The DLP9500UVFLN utilizes Digital Micromirror Device (DMD) technology. It consists of an array of microscopically small mirrors that can be individually tilted to either reflect or not reflect light. By controlling the tilt of each mirror, the device can create complex patterns by selectively reflecting light onto a target surface. This enables precise control over the projected image or pattern.

Detailed Application Field Plans

The DLP9500UVFLN finds applications in various fields, including:

- 3D Printing: It can be used to generate high-resolution patterns for layer-by-layer curing of UV-sensitive resins, enabling the creation of intricate 3D structures.

- Lithography: The device is suitable for maskless lithography systems, where it can project precise patterns onto a photoresist-coated substrate, facilitating the fabrication of microstructures.

- Advanced Imaging Systems: It can be integrated into advanced imaging systems, such as fluorescence microscopy or digital pathology, to enable high-speed and high-resolution image acquisition.

Detailed Alternative Models

- DLP9000UVFLN: Similar to the DLP9500UVFLN, this model offers high-resolution UV pattern generation but with a lower frame rate.

- DLP6500UVFLN: This model provides a lower resolution but at a more affordable price point, making it suitable for applications that do not require ultra-high resolution.

In conclusion, the DLP9500UVFLN is a high-resolution and high-speed Digital Micromirror Device designed specifically for UV applications. Its compact package, UV compatibility, and flexible control interface make it an ideal choice for various applications in fields

Enumere 10 preguntas y respuestas comunes relacionadas con la aplicación de DLP9500UVFLN en soluciones técnicas

Sure! Here are 10 common questions and answers related to the application of DLP9500UVFLN in technical solutions:

Q: What is the DLP9500UVFLN? A: The DLP9500UVFLN is a digital micromirror device (DMD) from Texas Instruments that uses micro-electro-mechanical systems (MEMS) technology to enable high-speed, high-resolution light modulation.

Q: What are the key features of the DLP9500UVFLN? A: The key features of the DLP9500UVFLN include a resolution of up to 1920 x 1080 pixels, fast switching speeds, high optical efficiency, and compatibility with ultraviolet (UV) light sources.

Q: How can the DLP9500UVFLN be used in 3D printing applications? A: The DLP9500UVFLN can be used as a light engine in 3D printers to selectively cure photopolymer resins layer by layer, allowing for the creation of highly detailed 3D printed objects.

Q: Can the DLP9500UVFLN be used in lithography systems? A: Yes, the DLP9500UVFLN can be integrated into lithography systems to pattern photoresist layers on semiconductor wafers, enabling the fabrication of microchips and other electronic components.

Q: Is the DLP9500UVFLN suitable for maskless lithography applications? A: Absolutely! The DLP9500UVFLN's high resolution and fast switching speeds make it well-suited for maskless lithography, where patterns are directly projected onto the substrate without the need for physical masks.

Q: Can the DLP9500UVFLN be used in digital signage and projection systems? A: Yes, the DLP9500UVFLN can be integrated into digital signage and projection systems to create high-resolution, vibrant displays and projectors with excellent color accuracy.

Q: What are some other applications of the DLP9500UVFLN? A: Apart from 3D printing, lithography, and digital signage, the DLP9500UVFLN can also be used in medical imaging, spectroscopy, biotechnology, and advanced manufacturing processes.

Q: Does the DLP9500UVFLN require any special cooling or power requirements? A: The DLP9500UVFLN does not have any specific cooling requirements, but it is recommended to follow Texas Instruments' guidelines for thermal management. It operates on a standard power supply voltage.

Q: Can the DLP9500UVFLN be controlled and programmed easily? A: Yes, the DLP9500UVFLN can be controlled and programmed using software development kits (SDKs) provided by Texas Instruments, making it easy to integrate into various technical solutions.

Q: Where can I find more information about the DLP9500UVFLN and its applications? A: You can find more detailed information about the DLP9500UVFLN, including application notes, datasheets, and technical resources, on the official Texas Instruments website or by contacting their sales representatives.